The reason why the fan cannot start

Capacitor open circuit, short circuit or insufficient capacity – After turning on the electric fan motor, the quality of the electric fan capacitor can be detected by a 500V insulation resistance metere. The method is to connect the two leads of the capacitor to the 500V insulation resistance meter respectively, and the resistance value of the insulation resistance meter ought to be zero at the beginning of the detection, which will swiftly rise to hundreds of megohms. Then remove the insulation resistance meter and short-circuit the two leads of the capacitor. Immediately, you will hear the sound of discharge and facility will generate sparks, indicating that the capacitor is neither short-circuit nor open-circuit, otherwise you are supposed to replace the electric fan capacitor.

Keyword: table cooling fan works, best table fan in tamil nadu, 8 table fan, buy table fan table, custom table fan images, desk fan with timer, table fan repair near me, table fan price in germany, buy table fan much, 6 usb desk fan, charging table fan price, table fan company 3rd, table fan distributor delhi, table fan factory reviews, table cooling fan nz.

Poor contact of cover winding or open circuit of stator winding – Turn on the electric fan motor, seek the fault point, re-solder, and in the meantime, chase down the open circuit of the stator winding, and re-connect it; when the electronic winding is seriously damaged, substitute it with a new winding.

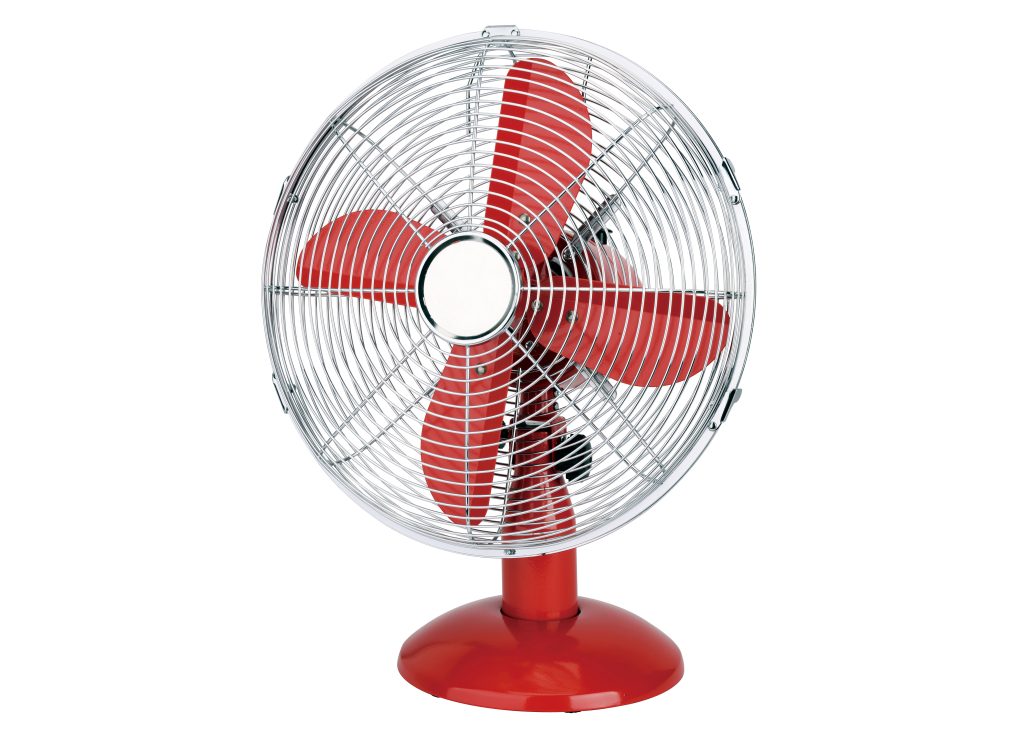

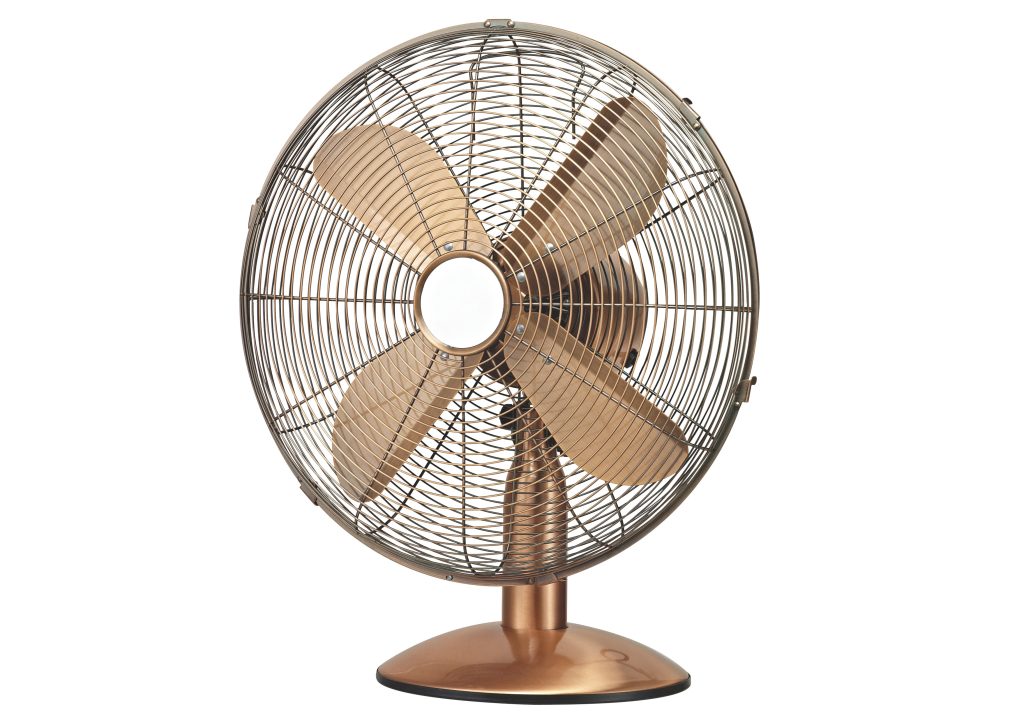

Model Number: FT-25MC

Input Power: 30W

input voltage: 220-240V~50Hz

Color: Chrome/Copper/Black/Red/Blue/Pink/White/Silver/Other color

OEM support : Yes

Certification: CE/GS/ETL/CB

Keyword: table fan wholesale direct, table fan company warranty, table fan vendor help, table fan manufacturer to cooler, table fan seller dallas tx, table cooling fan electricity consumption, good table fan, custom table fan oscillating, table fan price under 2000.

Electric fan coil winding open circuit – Find out the broken point and carry out welding treatment. When the number of broken wires is large and the damage is serious, it is indispensable to rewind the electric fan motor winding.

Keyword: table fan manufacturer qatar living, 7 blade cooling fan, custom table fan 3 speed connection, quiet small table fan, custom table fan circular, table fan maker 2017, buy table fan into, table fan wholesaler buy, small table fan price in pakistan.

No power supply voltage or the power supply voltage is too low – First, utilize a multimeter to measure whether the voltage is normal. If there is no voltage, you should inspect the circuit; if the voltage is too low, you are supposed to find out the cause and restore the regular voltage.

Keyword: table fan vendor up ideas, pedestal fan wholesale uk, table cooling fan 6v, table fan manufacturer japan, table fan cooling ideas, table fan factory gujrat, table fan wholesale auto group, desk fan oscillating, desk fan home bargains, 8 inch table fan.

The electric fan bearing is too tight or too loose – Excessive loose bearing hole of electric fan will cause friction between stator and rotor. We are supposed to open the electric fan motor and replace the bearing when the bearing is too loose; When the bearing is too tight, we need to open the electric fan to clean and refuel the bearing or adopt the reamer to properly loosen the bearing hole to make it rotate flexibly.

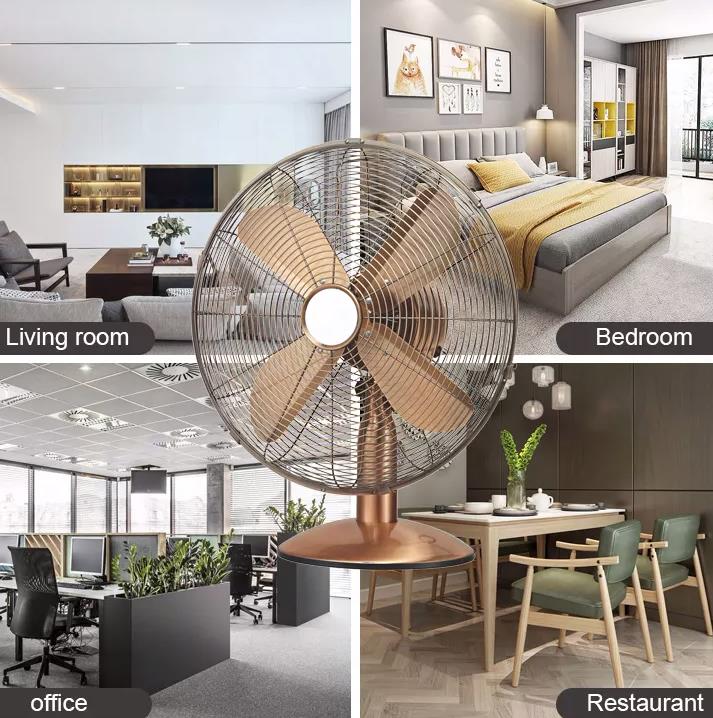

We SEEMAX majoring in developing and manufacturing cooling fan,air cooler, warming heaters and AC/DC motor, which are certified by GS mark,CE, ETL, RoHS,etc. Any needs please feel free to contact us!

Account manager : Mr.Michael Yan

Email : michael@seemaxfan.cn

WhatsApp & WeChat : 86-13416083266

Website : https://seemaxfan.cn