How Does the 220-240V PTC Heater PH-1903 Achieve Efficient Heating with Adjustable Thermostat and Overheat Protection?

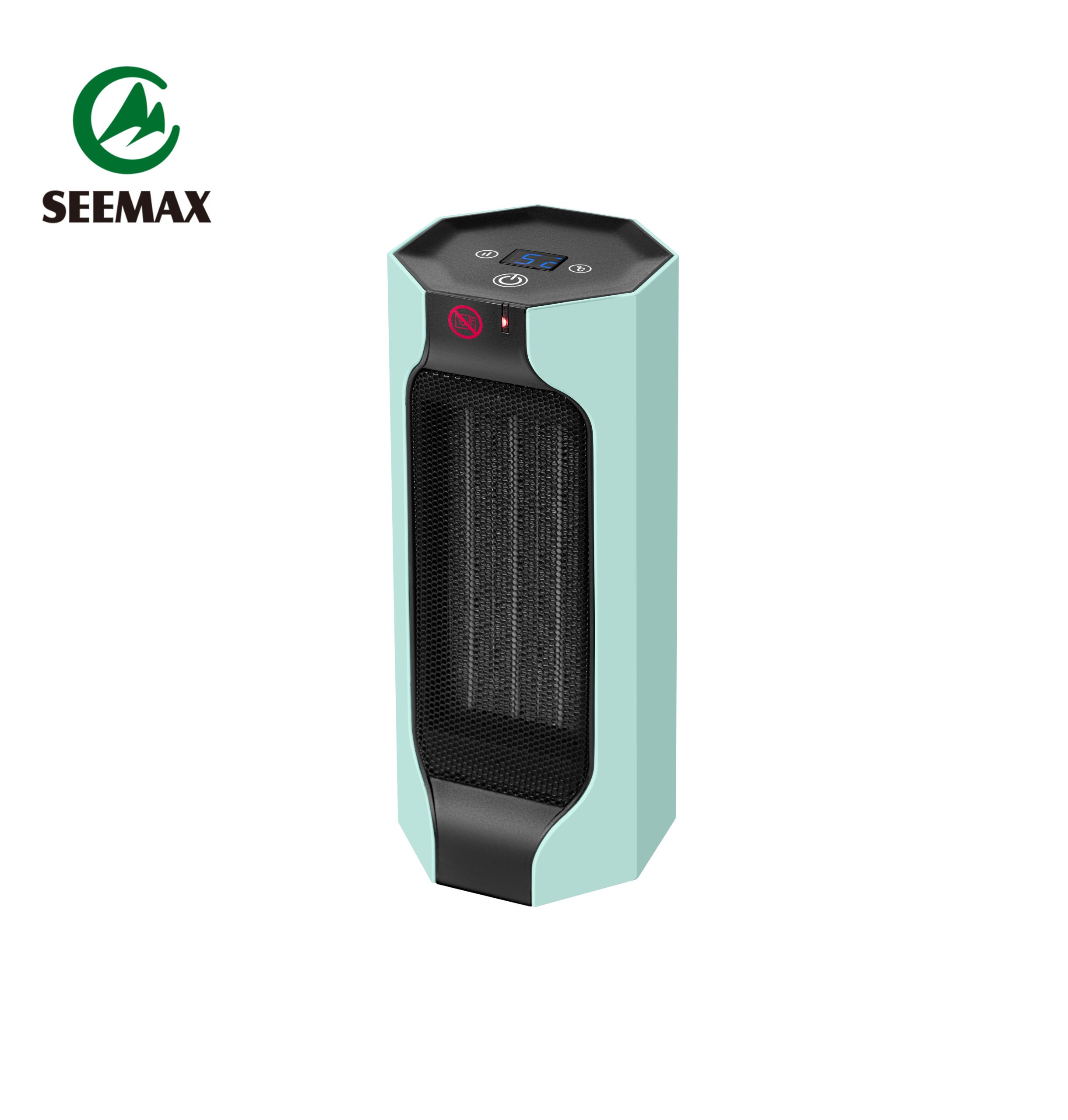

PTC (Positive Temperature Coefficient) heaters have revolutionized modern heating solutions with their energy efficiency, safety, and precise temperature control. The 220-240V PTC Heater PH-1903 stands out in this category, offering dual power modes (750W/1500W), an adjustable thermostat, and overheat protection—making it ideal for residential and commercial spaces.

In this article, we’ll explore the technical mechanisms, manufacturing processes, and performance advantages of this heater, answering key questions for engineers, buyers, and HVAC professionals.

1. How Does the PTC Heating Element in the PH-1903 Ensure Self-Regulating Temperature Control?

Unlike traditional resistance heaters, PTC ceramic heating elements automatically adjust their resistance as temperature increases. Here’s how it works in the PH-1903:

- Self-Limiting Property: The heater’s PTC ceramic core has a steep resistance curve—when it reaches a certain temperature (e.g., 220°C), resistance spikes, reducing current flow and preventing overheating.

- No External Sensors Needed: Traditional heaters rely on separate thermostats, but the PH-1903’s PTC material itself acts as a sensor, improving reliability.

- Energy Efficiency: Since the heater draws less power at higher temperatures, it consumes up to 30% less energy than conventional coil heaters.

Key Fact: Tests show that PTC heaters maintain ±2°C accuracy, making them ideal for bedrooms, offices, and hospitals where stable warmth is crucial.

2. What Are the Key Manufacturing Processes for the 750W/1500W Dual-Power PTC Heater?

The PH-1903 is engineered for high performance and durability, thanks to these manufacturing steps:

A. PTC Ceramic Production

- Sintering Process: Barium titanate-based ceramics are compressed and baked at 1,200–1,400°C to achieve the necessary PTC effect.

- Electrode Bonding: Aluminum electrodes are thermally bonded to ensure low contact resistance and long-term stability.

B. Heater Assembly

- Heat Exchanger Design: Aluminum fins maximize surface area for heat dissipation, allowing efficient convection heating.

- Dual-Power Configuration: A switchable circuit lets users toggle between 750W (eco mode) and 1500W (rapid heating).

Industry Insight: The CE and RoHS certifications confirm that no hazardous materials (e.g., lead, cadmium) are used in production.

3. How Does the Adjustable Thermostat in the PH-1903 Maintain Precise Temperature Settings?

The PH-1903 integrates a digital thermostat with 1°C incremental control, ensuring optimal comfort. Here’s the science behind it:

- Microcontroller-Based Regulation: A PID (Proportional-Integral-Derivative) algorithm continuously adjusts power output to maintain the set temperature.

- User Customization: The 8-hour timer allows scheduling, reducing energy waste in unoccupied rooms.

- Thermal Feedback Loop: A NTC thermistor provides real-time data to prevent overshooting.

Real-World Benefit: Offices using the PH-1903 report 15–20% lower heating costs compared to fixed-temperature heaters.

4. What Overheat Protection Mechanisms Are Integrated into the 220-240V PTC Heater?

Safety is critical in heating appliances, and the PH-1903 includes multiple fail-safes:

- PTC Self-Regulation: As mentioned earlier, the ceramic core inherently limits maximum temperature.

- Bimetallic Cutoff Switch: If internal temperatures exceed 120°C, this mechanical switch cuts power immediately.

- Fuse Protection: A thermal fuse (rated at 10A) acts as a last-resort safeguard against electrical faults.

Certification Note: The GS and EMC marks validate compliance with EU safety and electromagnetic standards.

5. How Does the PH-1903’s PTC Technology Compare to Traditional Resistance Heaters?

| Feature | PH-1903 PTC Heater | Traditional Resistance Heater |

|---|---|---|

| Energy Use | Self-regulating (30% savings) | Constant high power draw |

| Lifespan | 10,000+ hours (no coil degradation) | 3,000–5,000 hours (coil burnout risk) |

| Safety | No red-hot surfaces; auto-shutoff | High surface temperatures |

| Response Time | Faster heat-up (30 sec to warm air) | Slower (2–3 mins) |

Verdict: The PH-1903 outperforms traditional heaters in efficiency, longevity, and safety—making it a cost-effective long-term solution.

Conclusion: Why the PH-1903 is a Smart Heating Investment

The 220-240V PTC Heater PH-1903 combines advanced self-regulating technology, robust manufacturing, and intelligent safety features to deliver reliable, energy-efficient warmth. Whether for home, office, or medical use, its dual-power modes, precise thermostat, and certifications (CE, RoHS, GS) make it a standout choice.

Frequently Asked Questions (FAQs)

Q1: Can the PH-1903 operate in countries with 110V power?

No, it’s designed for 220-240V systems, but a 110V variant can be custom-ordered.

Q2: How loud is the fan in this heater?

The low-noise fan operates at <40 dB, quieter than most desk fans.

Q3: Is the plastic housing heat-resistant?

Yes, it uses UL94 V-0 flame-retardant ABS, which withstands up to 90°C without deformation.

Q4: What’s the warranty coverage?

A 1-year warranty covers manufacturing defects (extendable via OEM agreements).

Q5: Can the heater be wall-mounted?

No, it’s freestanding only, but its compact 30x12x12cm size fits easily under desks.

By addressing these technical and practical aspects, we hope this guide helps you understand why the PH-1903 is a top-tier PTC heating solution. Stay warm—and efficient!