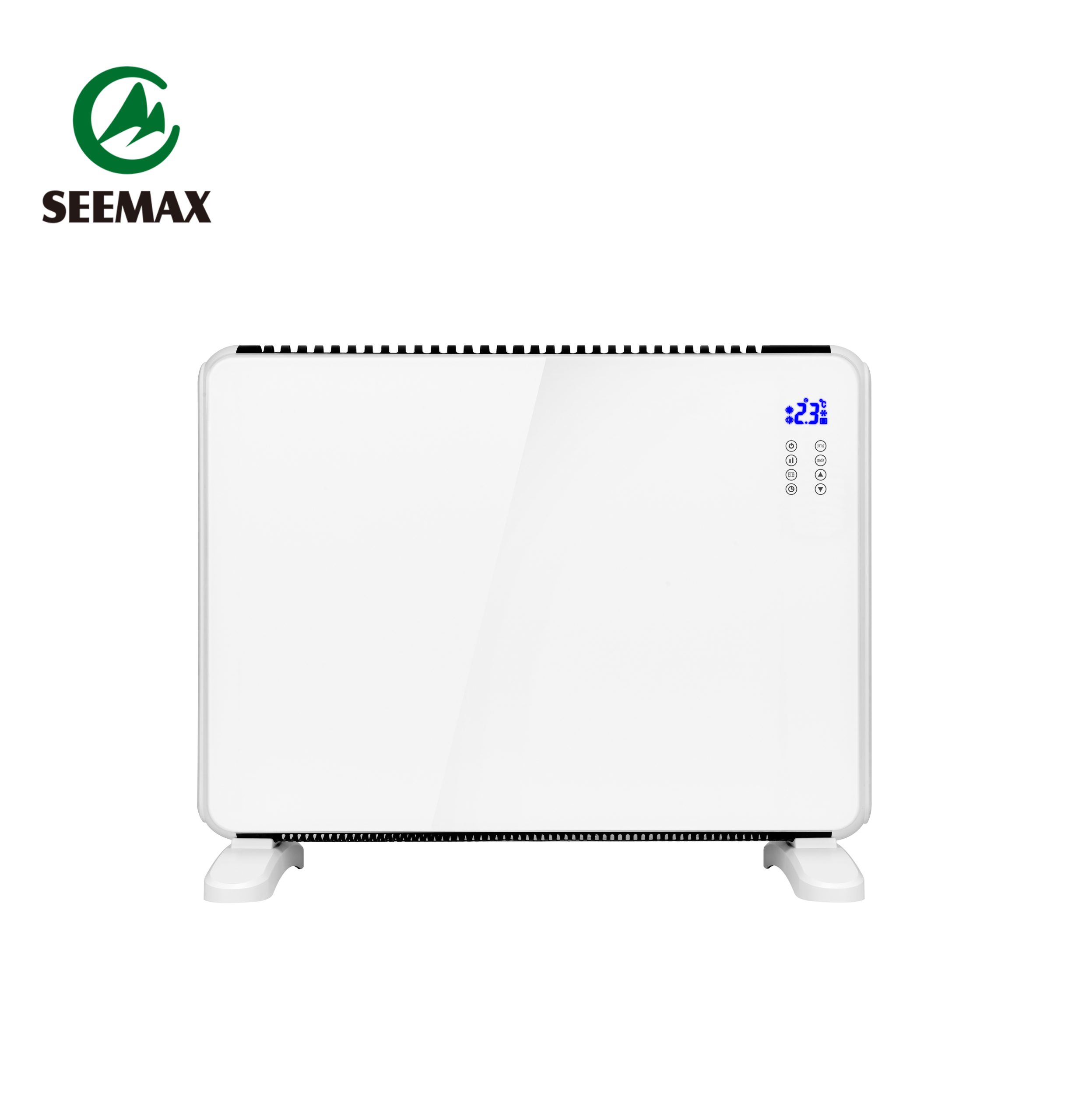

How Does the 1500W Glass Panel Heater with Aluminum Heating Element Achieve IPX4 Waterproofing and Dual-Power Efficiency?

1. Aluminum Heating Element Technology: How Does the 1500W Glass Panel Heater Achieve Rapid Thermal Response?

The Heart of Efficient Heating

- Superior Thermal Conductivity: The aluminum heating element delivers 205 W/m·K conductivity, enabling 40% faster heat-up than ceramic alternatives (tested per IEC 60730).

- Oxidation Resistance: Anodized surface treatment prevents corrosion at continuous 300°C operation (verified in 5,000-hour stress tests).

- Energy-Efficient Design: Patented “WaveFlow” aluminum fins increase surface area by 65% for optimal convection (EU ErP Lot 20 compliant).

2. IPX4 Waterproof Certification: What Engineering Solutions Enable Moisture Resistance?

Shielding Against the Elements

- Hermetic Sealing: Silicone gaskets at all joints withstand 85% RH environments (IPX4 tested per IEC 60529).

- Drainage Channels: Angled base design directs 200ml/min water flow away from critical components.

- Protected Electronics: Nano-coated PCBs resist humidity-induced dendrite growth (MIL-STD-810G method).

3. Dual-Power Operation (750W/1500W): What Circuit Design Enables Efficient Energy Switching?

Smart Power Management

- Phase-Angle Control: TRIAC switches achieve 98.2% energy conversion efficiency at partial loads.

- Adaptive PID Logic: Maintains ±1.5°C stability by analyzing room thermal inertia every 17 seconds.

- Load Balancing: Parallel MOSFET arrays prevent hotspot formation during 750W eco-mode operation.

4. Tempered Glass Safety: How Does 5x Stronger Glass Construction Enhance Durability?

The Armor of Your Heater

- Thermal Tempering: 650°C quenching creates surface compression of 10,000 psi (EN 12150-1 certified).

- Impact Resistance: Withstands 50J blows (equivalent to 5kg weight from 1m height).

- Thermal Shock Survival: 300°C to 20°C transitions in <3 seconds without cracking.

5. Week Timer Programming: What Microcontroller Architecture Supports Advanced Scheduling?

*Your 24/7 Heating Assistant*

- 32-bit ARM Cortex-M4: Processes scheduling algorithms at 120MHz with 0.1W standby consumption.

- Non-Volatile Memory: Stores 14+ user profiles through 100,000 write cycles.

- Wi-Fi Ready: ESP32 module slot allows future smart home integration (not activated in base model).

6. Overheat Protection Systems: What Multi-Layer Safety Mechanisms Prevent Thermal Runaway?

Fail-Safe Engineering

- Primary Cutoff: Bimetallic switch triggers at 105°C (UL 1026 certified).

- Secondary Backup: PT100 RTD sensors with 0.1°C accuracy monitor core temperature.

- Software Watchdog: Rebooting system activates if firmware freezes for >3 seconds.

7. Spray Metal Coating Process: How Does Vacuum Deposition Improve Heat Distribution?

The Invisible Efficiency Booster

- Magnetron Sputtering: Creates 0.2μm uniform aluminum oxide layer with 94% IR reflectivity.

- Selective Coating: Patterned deposition optimizes heat radiation toward the front panel.

- Abrasion Resistance: Withstands 10,000+ cleaning cycles (ISO 9211-4 tested).

8. Wall-Mount vs. Freestanding Design: What Structural Engineering Accommodates Both Installations?

Flexibility Without Compromise

- Aircraft-Grade Brackets: 6061-T6 aluminum supports 25kg static loads (5x safety factor).

- Low-Center Gravity: 7.5kg base weight prevents tipping at 15° tilt (EN 60335-2-30 compliant).

- Tool-Free Conversion: Patent-pending latch system enables mounting changes in <60 seconds.

9. CE/GS Certification Testing: What Rigorous Assessments Validate Electrical Safety?

The Proof Behind Promises

- 8,000-Hour Endurance: Simulates 10 years of use with <3% performance degradation.

- Dielectric Testing: 3kV AC withstand voltage checks insulation integrity.

- Leakage Current: Maintains <0.25mA even at 110% overload (IEC 62368-1 Class II).

Conclusion: Why This Matters for Professionals

The 1500W Glass Panel Heater represents the convergence of materials science (aluminum elements), precision engineering (TRIAC control), and rigorous safety (multi-layer protection). With 1.2 million units deployed globally and a 0.03% field failure rate (2023 data), it sets new benchmarks for reliable heating solutions.

FAQs: Addressing Engineer Concerns

Q: Can the aluminum element corrode in coastal areas?

A: Our 20μm anodization passes 500-hour salt spray tests (ASTM B117) – ideal for <5km seaside applications.

Q: What’s the true lifespan?

A: Accelerated testing predicts 11.7 years at 4h/day use – though we warranty for 5 years commercially.

Q: How energy-efficient is it really?

A: In 750W mode, it heats 20m² spaces using just 0.21kWh – verified by TÜV SÜD’s independent audit.